Controlling Weld Fume Exposure: Not an Easy Task

Prior to his retirement my father was a construction welder for over 30 years. The smell of metal fume was familiar to me at a young age. Weld fume has a way of staying on the clothes and skin. Having conducted exposure monitoring at dozens of weld shops and heavy manufacturing facilities I can say that welding techniques have not changed much since my father started welding in about 1980, and I gather neither has the intensity of weld fume exposure for welders. However, the epidemiologic and toxicologic information collected over the last 40 years has resulted in lower occupational exposure limits (OELs) for a variety of metal fumes.

Weld fume exposure is a complex topic, this article will focus on manganese and hexavalent chromium which I find are the most exceeded permissible exposure limits during weld fume exposure assessments. Before reading about the hazards, I have a question: Is clean air a recruiting tool?

Clean Air as a Recruiting Tool?

During my travels, many tradesman, human relations specialist, and operations managers have lamented that it is extremely difficult to hire and retain young welders. On the other hand, I have had welders make comments that reveal they are not happy with the air quality and want to know “How bad is it Joe?”.

Imagine you recently graduated trade school or finished an apprenticeship. Would you prefer to work in the shop with the thick brown and bluish haze overhead or the competitor’s shop across town with adequate local and general ventilation? A quick Google of the hazards of welding fume will quickly inform any would be welder of the hazards. Safety data sheets (SDS) and even some weld consumable packages (rod or wire) say, “Keep your head out the smoke”. What better way keep your head out the smoke than go across town to the nice clean shop with fancy ventilation hoods and top of the line welding hoods fitted with air purifiers?

“Do not breathe fumes that are produced by the arc welding operation. These fumes are dangerous. Keep the head and face out of the welding fumes.” - Warning from a popular welding equipment manufacturer.  |

Are the OSHA Permissible Exposure Limits Protective?

American Conference of Governmental Industrial Hygienist (ACGIH) Threshold Limit Values (TLVs) are revised annually to incorporate the latest scientific data. TLVs are used by professionals as guidelines and do not represent a strict separation between safe and hazardous environmental conditions. The guidelines are based upon the best available information from industrial experience, experimental human and animal studies and, when possible, a combination of the three. In 1971, OSHA adopted the then current TLVs (along with their limits) as the Permissible Exposure Limits (PELs). Since that time, OSHA has established individual health standards for approximately 25 chemical compounds. Because so many PELs have not been reviewed for over forty years, the TLVs represent a more appropriate basis to evaluate worker health exposures.

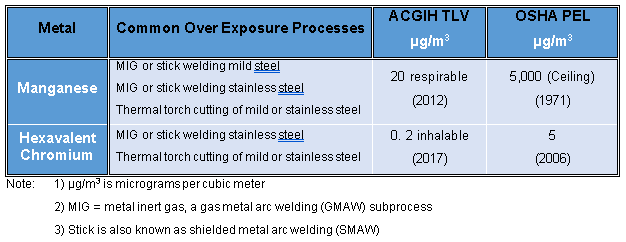

Manganese

The OSHA permissible exposure limit (PEL) for manganese of 5,000 microgram per cubic meter (µg/m3) is a ceiling limit, rather than 8-hour average, and has been unchanged since OSHA was established in the early 1970s. However, in 2012 the ACGIH set the manganese TLV to 20 µg/m3. The basis for the ACGIH TLV is reduction of the risk of irreversible central nervous system impairment, namely a Parkinson's-like disease called manganism which may result from chronic overexposure to manganese fume.

Hexavalent Chromium

In 2008, OSHA established a full health standard for hexavalent chromium (1910.1026) and lowered the PEL (that was in effect since the early 1970s) to 5 µg/m3. OSHA’s actions were based on new information about lung cancer, respiratory, skin and kidney effects. The TLV was also established at this level. However, in 2018, the ACGIH lowered the hexavalent chromium TLV to 0.2 µg/m3. The basis for the lower TLV* was new information about respiratory and skin sensitization. The TLV is designed to minimize respiratory sensitization and the likelihood of asthmatic responses in already sensitized individuals. Thus, the PEL is protective against cancer and other effects but may not be protective against respiratory sensitization. Employers should consider many approaches to meet the challenging TLV limits for manganese and hexavalent chromium. These might include: a change in the welding process or procedure to reduce the rate of fume production where consistent with application requirements, the use of alternate or improved engineering controls such as utilizing lower manganese emission electrodes, improved local exhaust ventilation, work practice improvements, and work process design changes. Should these or other options prove infeasible or inadequate, respiratory protection may also be necessary. Examples could include such as the use of half-mask respirators fitted with P-100 cartridges or positive pressure options like supplied air or Powered Air Purifying (PAPR) systems.

References:

Burgess, W. A. (1995). Recognition of health hazards in industry : a review of materials and processes. 2nd Edition.

Occupational Exposure to Hexavalent Chromium. (2006, February 28). Retrieved February 5, 2021, from Federal Register website: https://www.federalregister.gov/documents/2006/02/28/06-1589/occupational-exposure-to-hexavalent-chromium

--

Authored by Joe Johnson, CIH, CSP, CPH

Occupational Health and Safety Services Manager